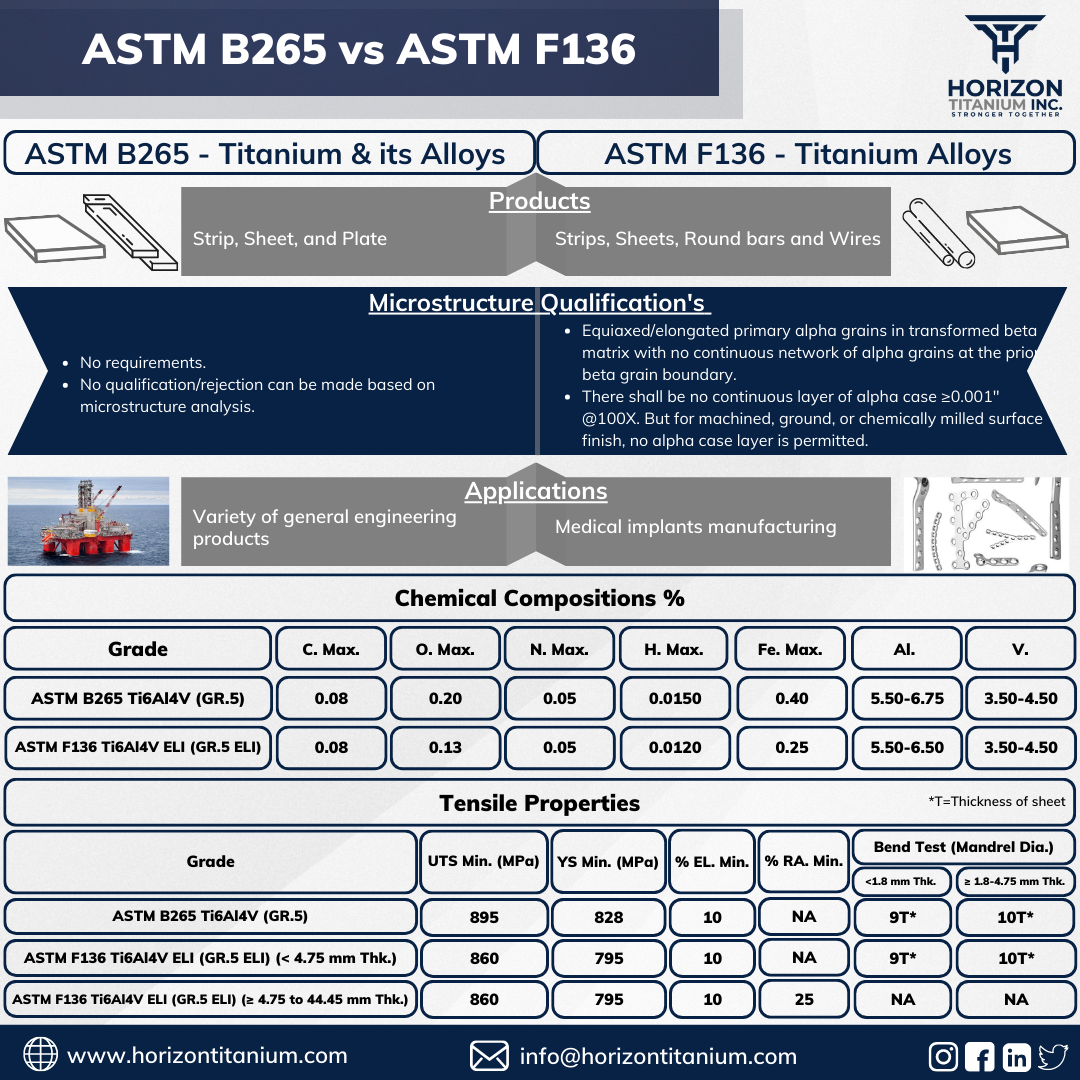

The ASTM B265 and ASTM F136 standards determine the quality of Titanium and Titanium alloys.

Chemical composition and microstructure influence the properties of Titanium.

After a doctor places a Titanium implant inside the patient’s body, they experience repetitive and unexpected loads. Titanium implants should have sufficient fatigue strength and fracture toughness to support this load to avoid implant failure.

ASTM B265 (Gr.5) Titanium materials may have an Alpha case in their microstructure which makes the Titanium material brittle. For this reason, ASTM B265 Titanium materials are unfit for Medical implant manufacturing applications.

On the other hand, there is a clearly defined microstructure requirement for ASTM F136 Titanium materials.

ASTM F136 (Gr.5 ELI) Titanium materials should not have an alpha case in their microstructure, making them ideal for medical implant applications.

For any information regarding Titanium metallurgy, its grades, standards, or applications, you can write us at info@horizontitanium.com