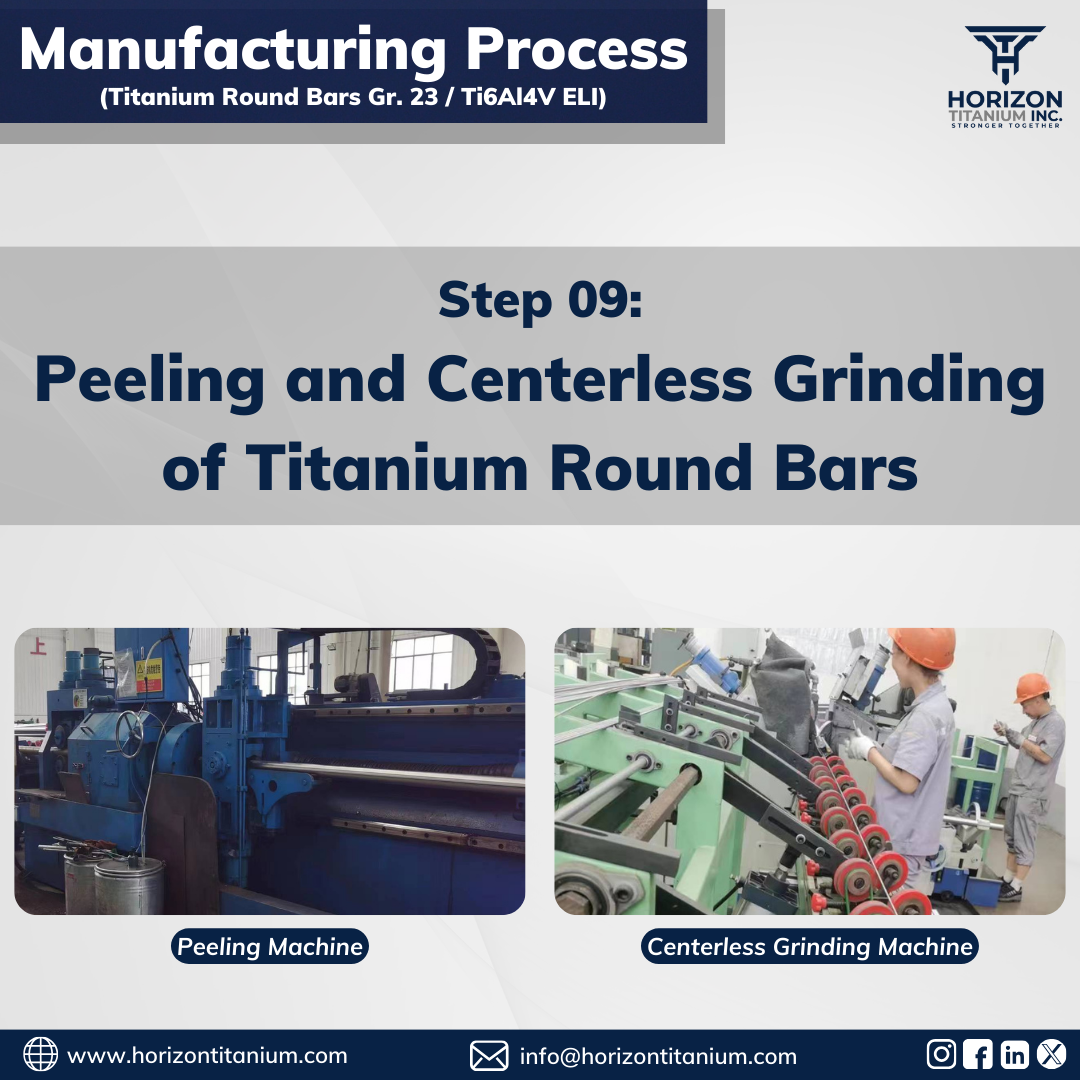

Horizon Titanium Inc.: Revealing the Titanium Bar Manufacturing Process

As we push forward in our commitment to perfect Titanium bar production, we’ve now arrived at a pivotal point—the ninth step. This phase revolves around the intricacies of Peeling and Centerless Grinding for Titanium Round Bars.

Distinguishing Process Parameters:

Peeling:

Controlled peel depth

Controlled feeding rate

Controlled workpiece temperature

Continuous coolant and lubrication

Peeling forces monitoring

Centerless Grinding:

Controlled workpiece speed

Controlled grinding wheel speed

Controlled residual stress

Controlled grinding wheel gap

Continuous coolant and lubrication

Distinguishing Peeled and Centerless Grinded Bars Quality:

Free from Alpha Case layer

Precise tolerance with a 10-micron diameter difference throughout the lot size

Mirror-finished surface

Free from surface imperfections

Stay tuned as we navigate this journey together, granting you a comprehensive view of our production methods. Our enthusiasm lies in unveiling each essential stage in the precise manufacturing of Titanium bars, exclusively intended for medical use.

For more information, please contact us at info@horizontitanium.com