Ductility is an important property for medical implant manufacturers because it allows them to give the desired shape to the raw materials during their manufacturing processes.

Ductility is measured in terms of % elongation during tensile testing.

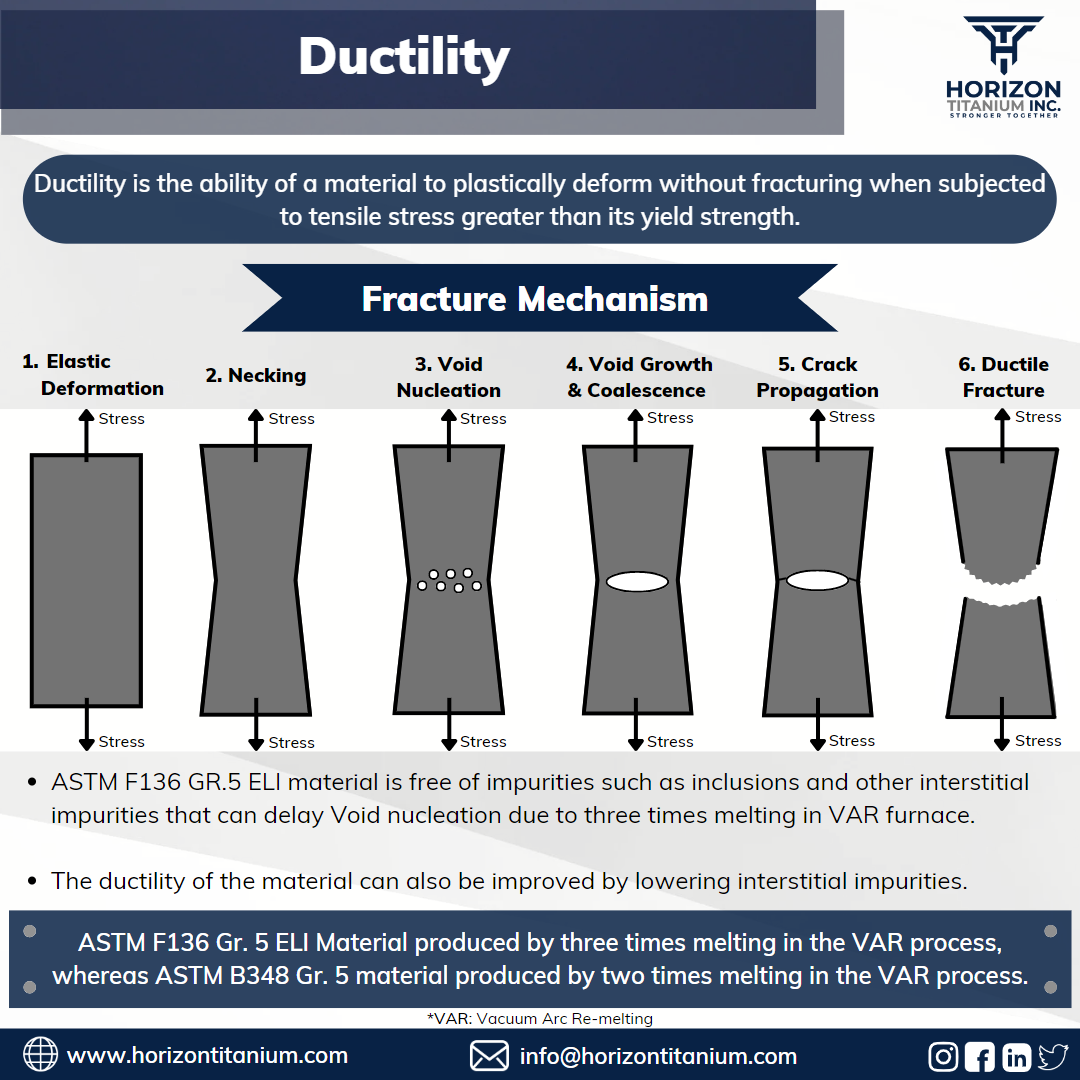

After the elastic limit (yield strength) is reached, a small fraction of the material’s cross-sectional area is reduced in a process known as necking.

At the necked part of the material, tiny cavities (voids) start to form as the load keeps rising. The voids enlarge with increasing tensile load and merge together to produce a crack that runs perpendicular to the applied stress. As a result, the material eventually fractures due to crack growth.

For more information on Titanium for medical applications, you can write to us at info@horizontitanium.com