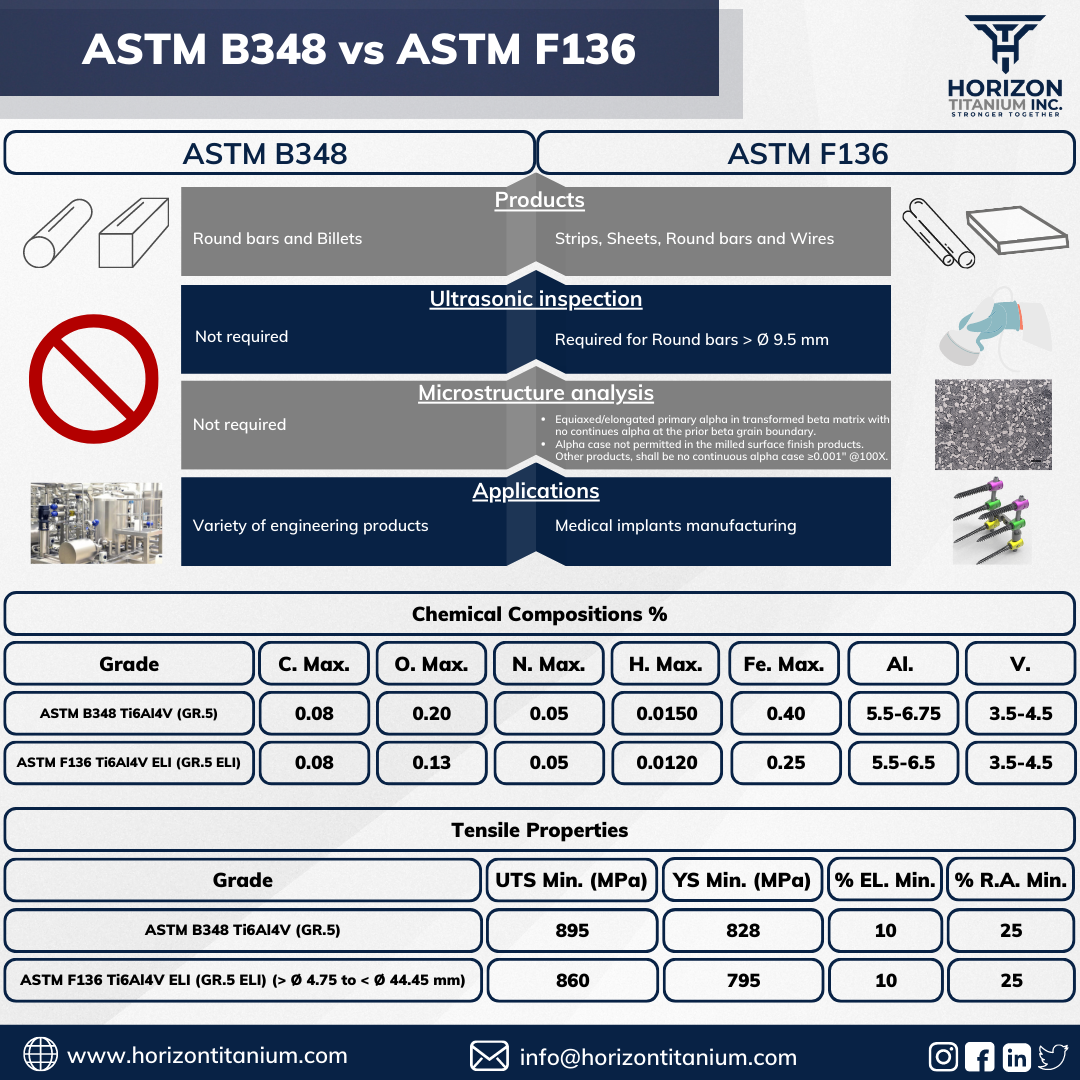

ASTM B348 and ASTM F136 standards apply to Titanium & its alloy products.

The chemical and mechanical requirements of the Titanium and its alloys are covered by ASTM B348 and ASTM F136 specifications, whereas ultrasonic and microstructure conditions are mentioned only under ASTM F136. ASTM F136 standard is applicable for medical implant applications and has stricter requirements.

An ultrasonic inspection ensures that material is free from internal flaws. Microstructure with an equiaxed/elongated alpha grain in a transformed beta matrix with no continuous network of alpha at prior beta grain boundaries throughout the material ensures superior mechanical property.

The alpha case is a brittle layer formed on the surface of Titanium due to the reaction of oxygen and nitrogen during the high-temperature manufacturing process. This brittle surface structure is prone to microcracking and diminishes the Titanium’s performance and fatigue properties.

There shall be no continuous layer of alpha case ≥0.001″ @100X. But for machined, ground or chemically milled surface finish, no alpha case layer is permitted.

For more information, kindly write us at info@horizontitanium.com.